Rock Wool Sandwich Panel For Clean Room

Min.Order Quantity: 10 Piece

Supply Ability: 1000Piece/ month

Original: GuangZhou China

Payment Terms: L/C,T/T

Certification: CE , ISO9001

Deliver time: 10-12 working day

- Description

- Inquiry

Rock Wool Sandwich Panel Introduction

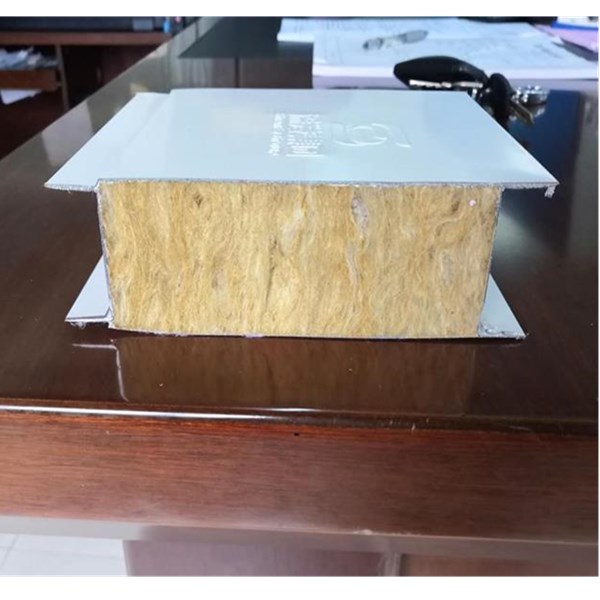

Rock wool sandwich panel is applicable to project with fairly high demand upon fire prevention. The rock wool fibers is vertical to the color steel plates. High density strip rock wool crisscross with the length of the color steel plate. All of this guaranteed the rock wool sandwich panel have a good bearing capability.

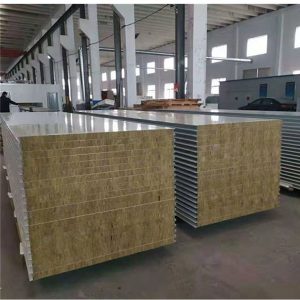

HaoAir Tech can provide all kinds of sandwich panel with different specification. It is widely used in clean workshop, the clean rooms of pharmacy, electronics, biology research, foodstuff, beverage ect.

Quick Detail

name: Rock Wool Sandwich Panel

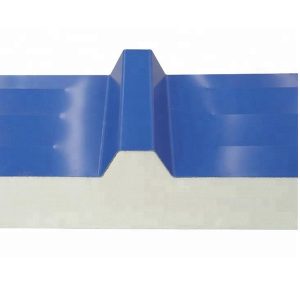

Effective width: 1150 mm/ 950 mm

Total board thickness: 50 mm-150 mm

Color steel sheet thickness: 0.3-0.6 mm

Materials: rock wool

Length: It is varied to meet customer’s requirement and transportation constraints

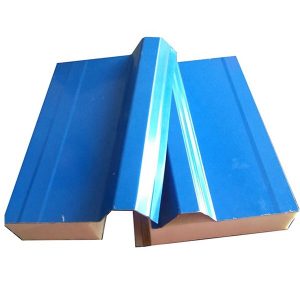

Installation: Rabbet joint(Tongue & Groove Type)

Rock Wool Sandwich Panel Applications:

It is widely used in :Purifying factory, combined house, building top attachment, indoor partition, automobile painting room, refrigerator and other project. Specially suitable for the place where is high requirement in the sound-insulation.

Advantages

1) Lower price and best quality

2) Waterproof and Fireproof

3) Fast installation and ease of handling

4) High strength

5) Durable

6) Heat insulation and Sound insulation

7) Energy-saving and Most area-saving

8) Environmental protection

9) Panels can be installed horizontally or vertically

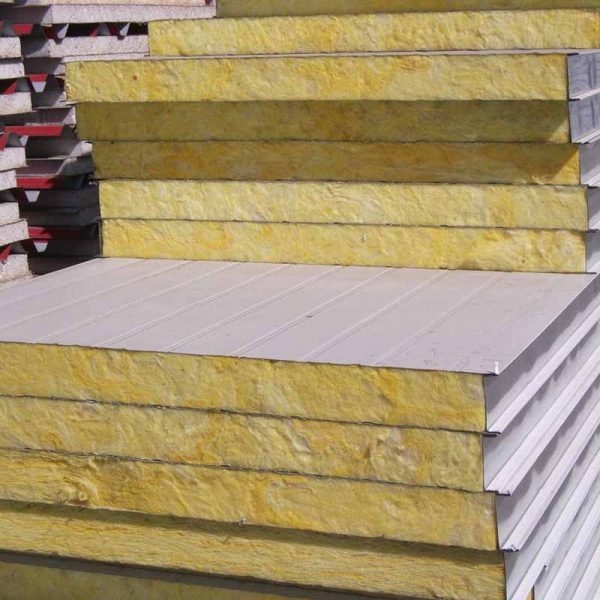

Introduction of sandwich panel

Sandwich panels are widely used in commercial and industrial steel building. Construction clean rooms for external walls, roofs, and ceiling panels. Due to the excellent performance of the insulation. Stone wool core sandwiched panels are commonly adopted for fire-resistance. And acoustic applications in these buildings.

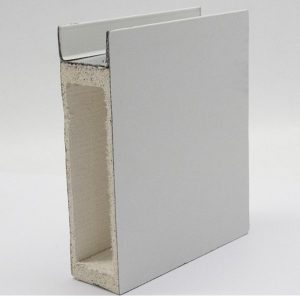

Sandwich panels generally consist of two outer metal sheets (steel or aluminum) with an insulation core sandwiched between them. The metal sheets are bonded to the insulation core with specialized adhesives. As the product is pre-fabricated in the factory. Stone wool core sandwich panels have been used successfully employed in various fast track construction projects.

Technical Parameter

Effective width | 950mm / 1150mm |

Length | depends on project’s requirement and transportation condition or according to customer’s request |

Materials | Polystyrene foam board(EPS/Rock wool/PU/Hollow glass sandwich panel/Paper Honeycomb/Aluminum honeycomb), Color steel sheet |

Structure | Upper and lower layer: Color steel sheet |

Middle: EPS/Rock wool/PU/Rock wool/Hollow glass sandwich panel/Paper Honeycomb/Aluminum honeycomb | |

Thickness | Color steel sheet: 0.3-0.6mm |

Total board: 50mm 75mm 100mm 125mm 150mm | |

Middle Material density | EPS:6-16kg/m3,Rock wool:100kg-200kg/m³ |

Conventional color | White,green,blue,Grey,red,etc |

Character | Light in weight, heat insulation, water resistant, green and environmental |

Use | Various roofs and walls referring to the large size factory buildings, storages, |