Sandwich Panel Core Materials

For the sandwich panel core materials, the thermal insulation, heat insulation and sound absorption of the color steel sandwich panel mainly depend on its core material – thermal insulation material. This kind of material not only needs good heat preservation, but also needs sufficient strength and rigidity. And it also has good adhesion with the color steel plate. Only in this way, the combined composite plate can withstand the design load and meet the building function requirements.

The classification of the sandwich panel core material

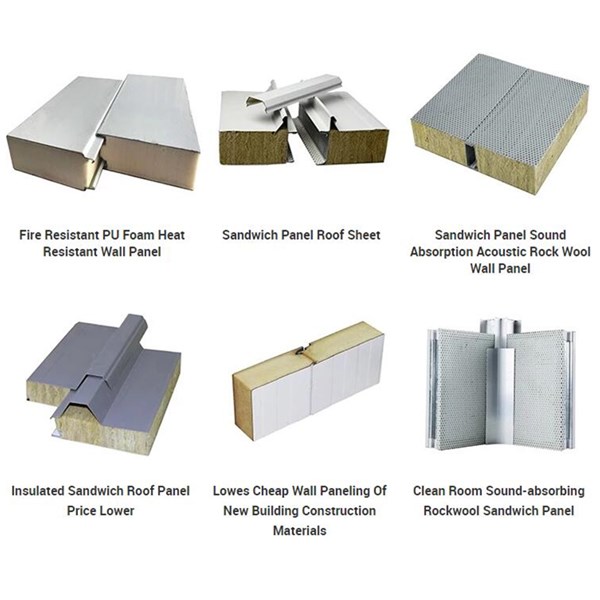

Color steel sandwich core material can be divided into two categories according to the chemical composition of its products. That is, organic chemical foam materials, such as polyurethane foam, polystyrene foam, phenolic foam, and trimeric foam. Wait. The other type is inorganic fiber materials, such as rock wool board, mineral wool board, glass wool board and the like.

Use status of the sandwich panel core material

At present, the most widely used color steel sandwich panel insulation core materials used in China color steel sandwich panel manufacturers are polystyrene sandwich panels (EPS sandwich panels) and rigid polyurethane sandwich panels (PU sandwich panels). The rock wool sandwich panel is the RW sandwich panel. However, organic materials such as polyurethane and polystyrene have low heat resistance, are easy to burn in case of fire. And are prone to generate toxic gas, which is one of the main factors of fire accidents.

Regulation

In recent years, building fire protection has been widely recognized by people. In some buildings, due to the use of insulation materials with poor fire performance, fire incidents are also endless. For example, the huge fire accident in the cultural center of CCTV New Site in February 9th, 2009 was caused by the fire caused by the use of flammable materials and unqualified insulation boards. Therefore, the national government attaches great importance to it.

On September 25, 2009, The laws issue: “Civil use The burning performance of building exterior insulation materials should be Class A and should not be lower than Grade B2. And Article 11 of Chapter 4 stipulates: “The metal sandwich composite sheet used for temporary residential buildings shall make of core material. Non-combustible or flame retardant insulation material.”

Disadvantage

However, the commonly used color steel sandwich panel core materials – polyurethane foam itself is not fireproof. And a large amount of smoke generated after combustion contains hydrogen cyanide, which is harmful to human health. In addition to not being fireproof, the polystyrene board will shrink and the outer insulation performance is also poor. Both polystyrene foam and polyurethane foam are flammable. Not resistant to high temperatures, seriously affecting the quality of construction projects and fire safety, and are currently restrict by the fire department. Although inorganic mineral cotton materials such as rock wool and glass wool can meet the fire prevention requirements. They are not environmentally friendly (the floating cotton wool is harmful to the human body during construction), easy to breed bacteria, have high water absorption rate, poor heat insulation effect, and insufficient strength. Good, short life.