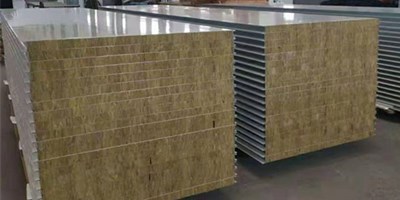

Magnesium sandwich panel brief introduction

Magnesium sandwich panel also kowns as glass magnesium sandwich panel. It is a three part system of MgO, MgCl2, and H2O, which is made by configuring and adding modifiers. It is a stable magnesium cement material with medium alkali. Glass fiber mesh is a new type of non-combustible decorative material. It is composed of reinforced materials and lightweight materials as fillers.

Processed by a special production process, it has the characteristics of fireproof, waterproof, odorless, non-toxic, non-freezing, non-corrosive, non-cracking, unchanged, non-combustible, high-strength, light-weight, convenient construction, long replacement, etc. It has compound special properties.

Magnesium sandwich panel Specification:

① Effective width:1150m

② Thickness:50mm, 75mm, 100mm(according to the requirement of customers)

③ Length:It depends on project requirement and transportation condition.

④ Core material:Glass magnesium hollow core, glass magnesium rock wool

⑤ Erection structure and application: Rabbet joint

Parameter

Product Name | Magnesium Sandwich Panel | ||

Surface | Galvanized Steel from 0.4mm-0.8mm | ||

Core Material | Magnesium oxysulfate material | ||

Color | Any Ral Color | ||

Fireproof Grade | Grade A (Nearly Non flammable) | ||

Insulation Value | 0.035-0.043 w/m*k | ||

Compressive Strength | 150-500 KPa | ||

Panel Thickness | 50mm,75mm,100mm,150mm,200mm | ||

Panel Width | 980mm/1180mm/950mm/1150mm | ||

Panel Length | As your requirement | ||

Service Life | 15-30 Years | ||

Advantages | Fireproof,Waterproof,Dust-proof,Anti-bacteria,Electrostatic Prevention,etc | ||

Applications:

It is widely used in: Indoor and outdoor boards for purifying factory building. Pharmacy, electronics, biology research, foodstuff, beverage etc.