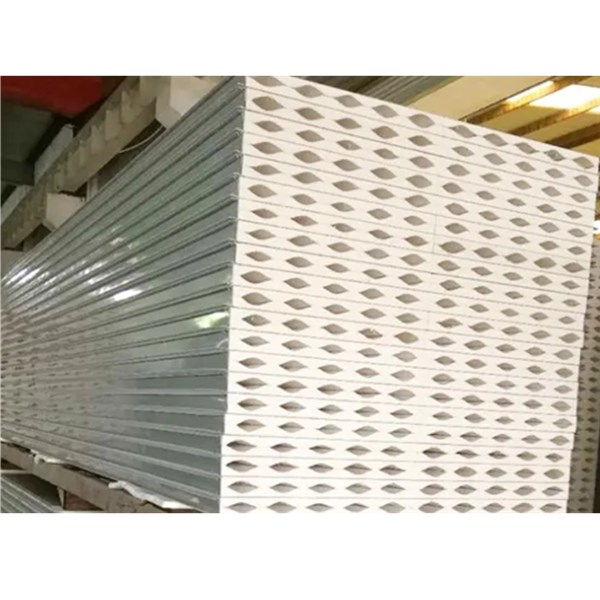

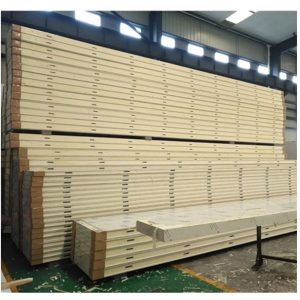

100mm Magnesium Oxysulfate Sandwich Panel

Payment & Shipping Terms:

Minimum Order Quantity: 10 set

Price: Negotiation

Packaging Details: Polywood packing

Delivery Time: 7-15 working days

Payment Terms: L/C, T/T, Western Union

Supply Ability: 500 sets per month

- Description

- Inquiry

Magnesium Oxysulfate Sandwich Panel Introduction

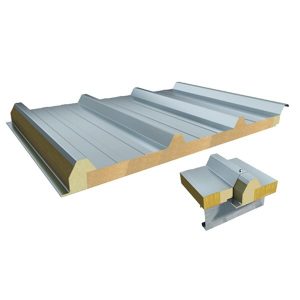

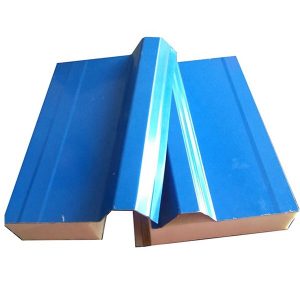

Magnesium oxysulfate sandwich Panel is composited by color precoated steel and magnesium oxysulfate strip or magnesium oxysulfate hollow plate. It gives full play to the unique properties of magnesium oxysulfate composites in terms of fire prevention, moistureproof, degumming prevent ion , high strength, heat preservation, heat insulation, sound-absorbing, etc,

Feature

1. Good fire resistance. The raw material of magnesium oxysulfate is non-combustible A1 level, Experiment shows that it can resist over 12000C. The fire-resistant time of 50mm thick magnesium oxysulfate sandwich plate is more than 1 hour, more than 2 hours for 75mm thick plate and more than 3 hours for 100mm thick plate.

2. Excellent thermal insulation performance: The thermal conductivity of magnesium oxysulfate 0.055W/M2K.

3. Waterpoof and moistureproof: the water absorption rate of magnesium oxysulfate plate is ≤0.8%. The magnesium oxysulfate sandwich panel has certain water permeability after absorbing water and is not likely to be out of shape irregularly, without any chemical reaction and with strong stability.

Specification:

Thickness of precoated steel sheet: 0.4—-0.8mm

Unit weight of Core material: 220—-280kg/m3

Thickness of the Panel: 50mm, 75mm, 100mm, 125mm. 150mm, 200mm

Installation Method: Rabbet Type (Tongue&groove)

Application

widely used as internal and external wall boards at purification workshops and space with high requirements on fire prevention and temperature preservation, such as hospital, electronics, food, cosmetics, pharmaceuticals, bioresearch, beverage and laboratory .

Magnesium Oxysulfate Sandwich Panel