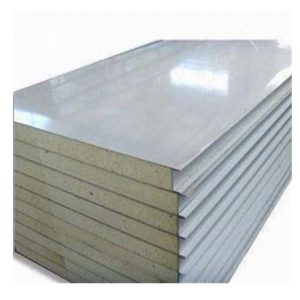

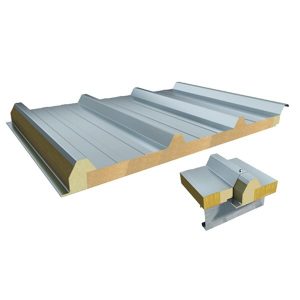

Hollow MgO Sandwich Panel

Payment & Shipping Terms:

Minimum Order Quantity: 10 set

Price: Negotiation

Packaging Details: Polywood packing

Delivery Time: 7-15 working days

Payment Terms: L/C, T/T, Western Union

Supply Ability: 500 sets per month

- Description

- Inquiry

Hollow MgO Sandwich Panel Introduction

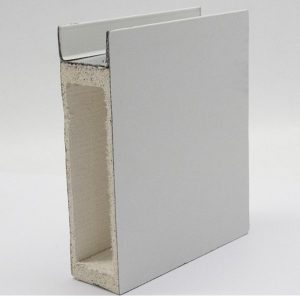

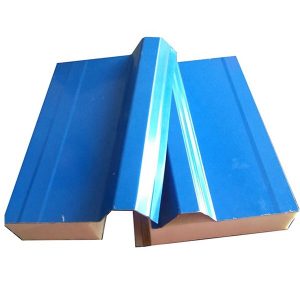

Hollow MgO Sandwich Panel is a magnesium oxide, magnesium chloride, and water ternary system. The configuration and adding modifier, stable performance of magnesia gelled material, with alkali glass fiber network in reinforced material, lightweight materials as filler compound and into a new type of incombustible decorates material. Using in indoor and outdoor boards for purifying factory building, combined house and indoor partition with high level requirement in fire proofing thermal insulation.

Hollow MgO Sandwich Panel Application

Worshop, temporary office/buiding, gymansia, villa, mobile building, guard booth, wall & roof materials for steel building or structure.

Hollow MgO Sandwich Panel Features:

1. Fire proof: 67minutes

2. Weather proof

3. High density

4. High temperature withstanding capacity more than 1000℃

Parameter

| Product name | Hollow Magnesium Oxide sandwich board | |

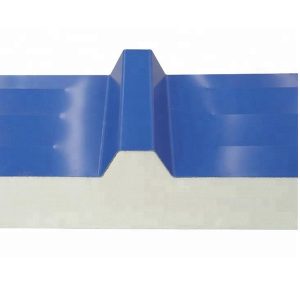

| Thickness | upper layer | 0.4mm-0.8mm |

| core material | 50mm-150mm | |

| bottom layer | 0.4mm-0.8mm | |

| Effective Width | standard | 950mm, 1150mm |

| other | can be customized | |

| Length | can be customized,less than 12m | |

| Density | 24kg/m3 | |

| Weight | up to model | |

| Color | Ral Standard | |

| Temp tolerance | 1500℃ | |

| Hydrophobic rate | ≥97.5% | |

| Fire resistance level | A (>70 minutes) | |

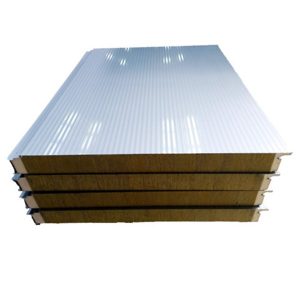

| Surface profile | flat,corrugated,big rib, small wave | |

| Compression bearing | 22Mpa(GB/T7019-1997) | |

| The shrinking rate when heated | 1.0%(GA160-1997) | |

| The rate of deformation when pick up the moisture | 0.26%(GA160-1997) | |

| Material | upper layer | color steel plate or stainless steel sheet (also can be |

| PPGI, galvanized sheet, condominium zinc plate, | ||

| printing steel plate, alumina foil paper, | ||

| PVC and Plywood) | ||

| inner layer | Magnesium oxide,magnesium chlo-ride,saw dust,perlite | |

| bottom layer | color steel plate or stainless steel sheet (also can be | |

| PPGI, galvanized sheet, aluminum zinc plate, | ||

| printing steel plate, aluminum foil paper, | ||

| PVC and Plywood) | ||

| Parts | Eccentric hook used for connection of panel | |

| Film covering for protecting the surface layer | ||

| Connection method | Capped for roof panel,Tongue and groove for wall panel | |

| Heat transfer coefficient | ≤0.041 W/M*K | |

| Characteristics | Sound insulation≥44db(GBJ121-88) | |

| Superior heat insulation, waterproof and damp resistant | ||

| Attractive appearance. | ||

| High density, bending resistance, can be sawing,nailing and sticking. | ||

| Eco-friendly | ||

| Freezing and cracking proof. | ||

| Weather proof | ||

| light weight,very easy to insulation and dismantling | ||

| safe,100% does not include the asbestos,formaldehyde,and benzene | ||

| Lifespan | >20 years | |

| Usage | Widely used in: Indoor and outdoor boards for purifying factory building, combined house and indoor partition with high level requirement in fire | |

| proofing and thermal insulation. E.g.Interior decoration of civil buildings | ||

| for medicine, electronics, biology research, foodstuff, beverage etc. | ||

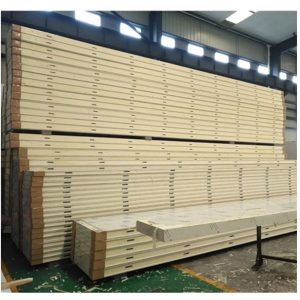

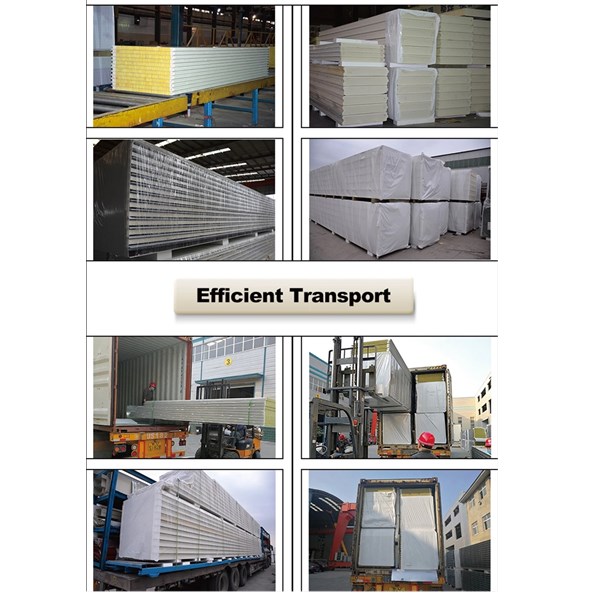

Efficient Transport

Hollow MgO Sandwich Panel